- Home Page

- Company Profile

-

Our Products

- Sewage Water Treatment Chemicals

- Calcium Acetate Based Defoamer

- Anhydrous Citric Acid

- Diammonium Phosphate

- Ferric Alum

- Caustic Soda Lye

- Ferric Chloride Lumps

- Non Ferric Alum

- Anionic Polyelectrolyte

- Poly Electrolyte

- Sodium Bisulphate

- Sodium Hypochlorite

- Sodium Meta Bi Sulphite (SMBS)

- Trichloroisocyanuric Acid Powder 90

- Liquid Sodium Hypochlorite

- Agriculture Grade Diammonium Phosphate

- Technical Grade Diammonium Phosphate

- Biocides Chemical Liquid

- Hydrochloric Acid Chemical

- Cattle Feed Supplements

- Lime Products

- Lime Products

- Hydrated Lime Powder

- Limestone Minerals

- Calcium Chloride

- White Quicklime Crystal

- Calcite Powder

- Fakki Lime

- Soap Stone Powder

- Hydrated Lime 90%

- Calcium Carbonate

- White Lime Powder Chunna For Construction

- White Calcite Powder

- Lime Stone Powder

- Calcium Oxide Powder

- Industrial Grade Calcite Powder

- Calcium Chloride Powder

- Fakki Lime Powder

- Calcium Hydroxide Hydrated Lime

- Cwic Hydrated Lime 95%

- Precipitated Calcium Carbonate

- Poultry Feed Supplements

- Industrial Chemical And Minerals

- Cleaning Products

- Alum

- Hydrate Lime

- Poly Aluminium Chloride

- Industrial Chemicals Powder

- Blue Copper Sulphate

- Crystal Manganese Sulphate

- Sulphur Powder

- Sulphamic Acid Descalant

- Calcium Chloride Powder

- Ammonium Chloride Powder

- Sulfamic Acid Powder

- Sodium Bicarbonate Food Grade

- Citric Acid Monohydrate

- Zinc Sulphate monohydrate

- Bentonite Powder - Calcium Based

- Industrial Grade Sulphur Powder

- Potassium Chloride Powder

- Activated Calcium Carbonate

- Soda Ash Powder

- Stearic Acid Granules

- Crystal Caustic Soda Flakes

- Sodium Metabisulfite

- Potassium Carbonate Powder

- Ferrous Sulphate Crystal

- Vitamin C Ascorbic Acid Powder

- Sodium Tripolyphosphate Powder

- Crystals Sodium Citrate

- Zinc Oxide Powder

- Boiler Treatment Chemical

- Water / Effluent Treatment Chemicals

- Industrial Chemicals & Minerals

- Hydrogen Peroxide Chemical

- Caustic Soda Flakes

- Talc Powder/Soap Stone Powder

- Magnesium Oxide

- Hydrochloric Acid ( HCL)

- Bentonite Powder

- Sulphuric Acid

- China Clay

- Ferric Chloride

- Formalin Chemicals

- Gypsum Powder

- Mono Ethylene Glycol

- Dolomite Powder

- Ferrous Sulphate

- Magnesium Sulphate

- Manganese Sulphate

- Glycerine Chemical

- Soda Ash

- Sodium Chlorite

- Zinc Sulphate

- Phosphoric Acid

- Potassium Permanganate

- Propylene Glycol Powder

- Stearic Acid

- T.R.O ( Turkey Red Oil)

- Isopropyl Alcohol

- Magnesium Chloride

- Caustic Potash

- Acid Slurry

- Boric Acid

- Ascorbic Acid

- Citric Acid

- Calcium Nitrate

- Tri-Sodium Phosphate

- Sodium Tri Poly Phosphate

- Zinc Chelate

- Manganese Chelate

- Chelated Magnesium

- Sodium Lauryl Sulphate

- Copper Dusting Powder

- DM Water

- Acetic Acid Glacial

- Boric Acid Chemical Powder

- Hydrazine Hydrate

- Nitric Acid

- Salt Powder

- Potassium Iodate

- Acetic Acid

- EDTA Powder

- Potassium Iodide

- Calcium Chloride Chemical

- Concentrated Nitric Acid

- Phosphoric Acid Chemicals

- Rock Phosphate Granules

- Rock Phosphate

- China Clay Powder

- Hydrogen Peroxide 50

- Godrej Propylene Gylcol

- Rock Phosphate Powder

- Liquid Isopropyl Alcohol

- Copper Sulphate Powder

- Sulphur Agri Powder

- Technical Grade Urea

- Sulphur Dusting Powder

- Peracetic Acid

- Cobalt Sulfate Powder

- Non ferric Aluminium sulphate Lumps

- Edta Mn Chelated Manganese

- Edta Mg Chelated Magnesium

- Power Supply bordo mixture

- Bentonite Powder- Sodium Based

- Cleaning Products & Housekeeping Products

- Boiler Cooling Water Chemicals

- Industrial Chemicals

- Industrial chemical

- Dicalcium Phosphate Powder

- Formalin Liquid Solution

- White Borax Powder

- Trace Minerals- Sulphates

- Trace Element With Copper Sulphate

- Aditya Birla Bleaching Powder

- Di Calcium Phosphate Rock Base

- Sodium Meta Bi Sulphite Food Grade

- Sodium Chlorite Liquid

- Poly Electrolyte Cationic

- Poly Electrolyte Anionic

- Sodium Thiosulphate Anhydrous

- Silicon Base Defoamer

- Distilled Water

- Microneutrients

- Waste Water Treatment Chemicals

- Aqua Feed Supplement

- Chemical Compound

- Sewage Water Treatment Chemicals

- Contact Us

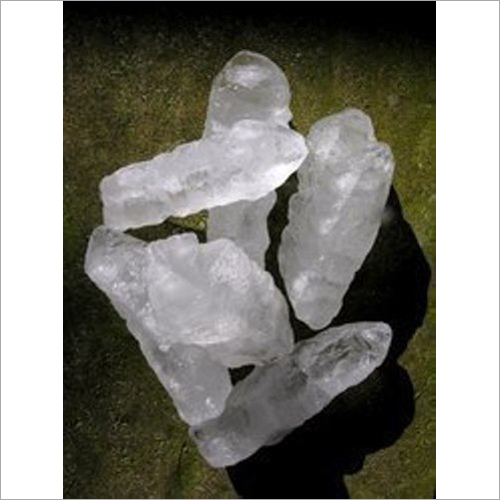

Ferric Alum Bricks

7.9 INR

Product Details:

- Chemical Name Other

- Physical Form Liquid

- Grade Industrial Grade

- Purity(%) 98 %

- Application Other

- Click to View more

X

Ferric Alum Bricks Price And Quantity

- 5000 Kilograms

- 7.9 INR

Ferric Alum Bricks Product Specifications

- Other

- Other

- Industrial Grade

- 98 %

- Liquid

Ferric Alum Bricks Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- 100 Kilograms Per Day

- 1 Days

- Yes

- Contact us for information regarding our sample policy

- West India, South India

Product Description

Specifications:

|

Product Description |

Product Specification |

|

1)Alum - Ferric Grade - I |

(Solid) Al2O3: 15-16% |

|

(Liquid) Al2O3: 7-8% |

|

|

2)Alum ( Non Ferric- Ammonia Alum) |

(Solid) Al2O3: 13%. |

|

(Powder) Al2O3: 13%, Moisture:15% |

Optimized for Industrial Lining

Designed specifically for heavy-duty industrial lining, ferric alum bricks offer outstanding thermal resistance, making them ideal for furnaces, kilns, and reactors. Their rectangular shape facilitates straightforward installation, and their low water absorption ensures durability even under fluctuating temperature and humidity conditions. Industries across India rely on these bricks for protective linings that withstand intense operational demands.

Superior Strength and Longevity

With a strong compressive strength and 98% purity composition, these bricks deliver exceptional performance in harsh environments. The high-quality materials reduce the risk of structural failure, while the reddish brown hue distinguishes them from standard linings. As a result, maintenance needs are minimized and operational life is extended, making them a smart investment for a range of industrial sectors.

FAQ's of Ferric Alum Bricks:

Q: How are ferric alum bricks manufactured for high thermal resistance?

A: Ferric alum bricks are manufactured using a precise blend of alumina, ferric compounds, and other industrial-grade materials. The process includes shaping the materials into rectangular forms and firing at high temperatures, which imparts exceptional thermal resistance and ensures strong compressive strength.Q: What benefits do ferric alum bricks provide in industrial lining applications?

A: These bricks offer significant benefits such as high thermal resistance, low water absorption, and formidable compressive strength. This combination safeguards equipment from heat and corrosion, supports structural stability, and reduces maintenance requirements for industries.Q: When should ferric alum bricks be selected over conventional lining materials?

A: Ferric alum bricks are preferable when applications demand superior thermal stability, low water absorption, and robust mechanical strength. They are especially suitable for environments exposed to high temperatures, chemical exposure, or continuous mechanical stress.Q: Where are ferric alum bricks commonly used within industrial settings?

A: These bricks are widely utilized in the construction of furnace linings, kilns, reactors, and similar high-temperature equipment across chemical plants, steel industries, and refineries throughout India.Q: What is the recommended process for installing ferric alum bricks?

A: Installation typically involves arranging the bricks in a staggered, interlocking pattern to ensure stability. Using industrial mortar or binding agents further secures the structure, while their rectangular shape aids in achieving a uniform, gap-free lining.Q: How does low water absorption enhance the performance of ferric alum bricks?

A: Low water absorption limits the risk of brick degradation when exposed to steam or humidity, helping to preserve strength and extend service life in demanding conditions.Q: What advantages do Indian manufacturers, suppliers, and traders offer for these bricks?

A: Indian manufacturers provide high-purity, reliable ferric alum bricks tailored to the specific requirements of domestic industries. Local sourcing ensures timely delivery, technical support, and compliance with prevailing industrial standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email